Display · Delivery · Training · Monitoring · Management · Emergency

Production · Equipment Operation and Maintenance · Enterprise Operation

Process · Equipment · Operations · Personnel

Visualized Wisdom Operation Management System

Double Benefits, Half Cost

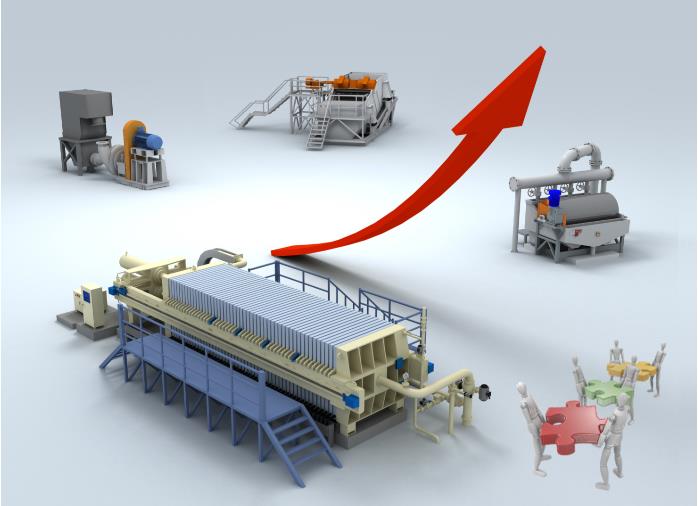

Enterprise can achieve the best return on investment at low operating costs through group intelligence, the use of cost-effective equipment and the best full-staff job responsibility management.

The best management + suitable equipment = the best benefits

Wisdom enterprise can achieve the following goals in competition:

Better profits using the same technology and equipment

Equal profits using older equipment and technology

Stay outstanding using better technology and equipment

The core process of operation management is to follow normality, prevent abnormalities, and promote improvement;

On-site abnormalities include: hidden equipment problems, process bottlenecks, and personnel risks;

The characteristics of on-site anomalies: hidden, random, massive, interrelated, occurring suddenly, frequently, simultaneously, from inside to outside, etc., so the anomalies is necessary to be managed use methods that meet the characteristics of abnormal events.

The digital twin of operation management focus on the operation period which is the main profit-generating period, and maps the three manifestations, two machines, and two originals (site, reality, real thing; mechanism, mechanism; principle, principle) of events in actual management with the scene; Improve the efficiency of operation and management.

By modeling physical plant, including equipment, work space and processing space, digital twin architecture provides augmented 3D contexts for enterprise manage job responsibilities and achieve collaboration. It helps enterprise optimize operations and make the process evaluation, inspection, implementation, deployment, decision-making, and problem discovery more accurate and efficient.

Powerful tool for improving operational efficiency

Basis of position management mechanism

Basis of closed-loop of data from collection to application

Highlighting the value of data by complete management of large-scale low-value data

Basis of full life cycle, predictability and lean management

Basis of quantification of experience, knowledge transfer and application

Path of digital transformation and turn to wisdom enterprise Implement digital twin architecture Achieve augmented 3D contextual data management Build a digital twin for operation management Build a foundation for a wisdom operation management system Achieve corporate operational benefits

Process of implementing operational management digital twin architecture 3D modeling for plant and equipment 3D modeling for processing space and working space 3D modeling for symbols 3D models conversion – lightweighting -- importing Introduce basic management tools Integrate with management new thinking Establish a smart enterprise operation management structure Benchmar operation management standards Embed operation management process Integrate various offline and online technologies Lead existing information systems Achieve 3D panoramic live operation navigation

Make prediction of the deterioration of the hidden problems by collecting and analysizing the image data that indicating the abnormalities, improve the efficiency and accuracy of abnormality management decision-making

Achieve lean management, all employees coordination, improvement of quality, delivery time, and cost control by archiving massive data using augmented 3D contexts

Digital twin enables enterprise manage every field event in a closed-loop way, make trial and error at a low-cost and low risk, make spiral progress and orderly, fast development

Set up the goals of informatization construction: To make cognition, communication, and collaboration of all employees are unified, efficient, economical, burden-reducing, and fault-tolerant. lead informatization construction and build a wisdom operation management system with group intelligence and high participation of all employee

Make complete and accurate data collection and closed-loop data application management. Achieve rapid value extraction from low value density data. Bring unstructured data like images, videos, voice data into management. Enable data management evolve from simple storage and recovery to content-based or semantic relationship-based data archiving and application

Operation management digital twin architecture can fully present enterprise management capabilities as well as limitations of the production. It can also enable the leader to carry out incentive management for all staff and manage the limitations of the production, and greatly enhances the competitiveness of enterprise

We promise: the customized operation management digital twin structure is "Affordable, Available, Achievable", benchmarks the indicators of enterprise core competitiveness (per capita labor productivity, unit product total delivery cost, and operating investment return rate) , and helps enterprises improve management efficiency greatly

Establishment of operation management digital twin architecture. Continuous services of equipment inspection, diagnosis and data consolidation. Establishment of knowledge cloud database for equipment diagnosis and adjustment

Continuous research and development on data archiving using augmented 3D context Borrow insights from the world‘s advanced enterprise management thinking, methods and tools, and integrate them into the digital twin architecture. Study how the digital twin architecture use case drives digital transformation and operation management changes in the internet age

The following shows part of the authorized registered trademarks and patented technologies